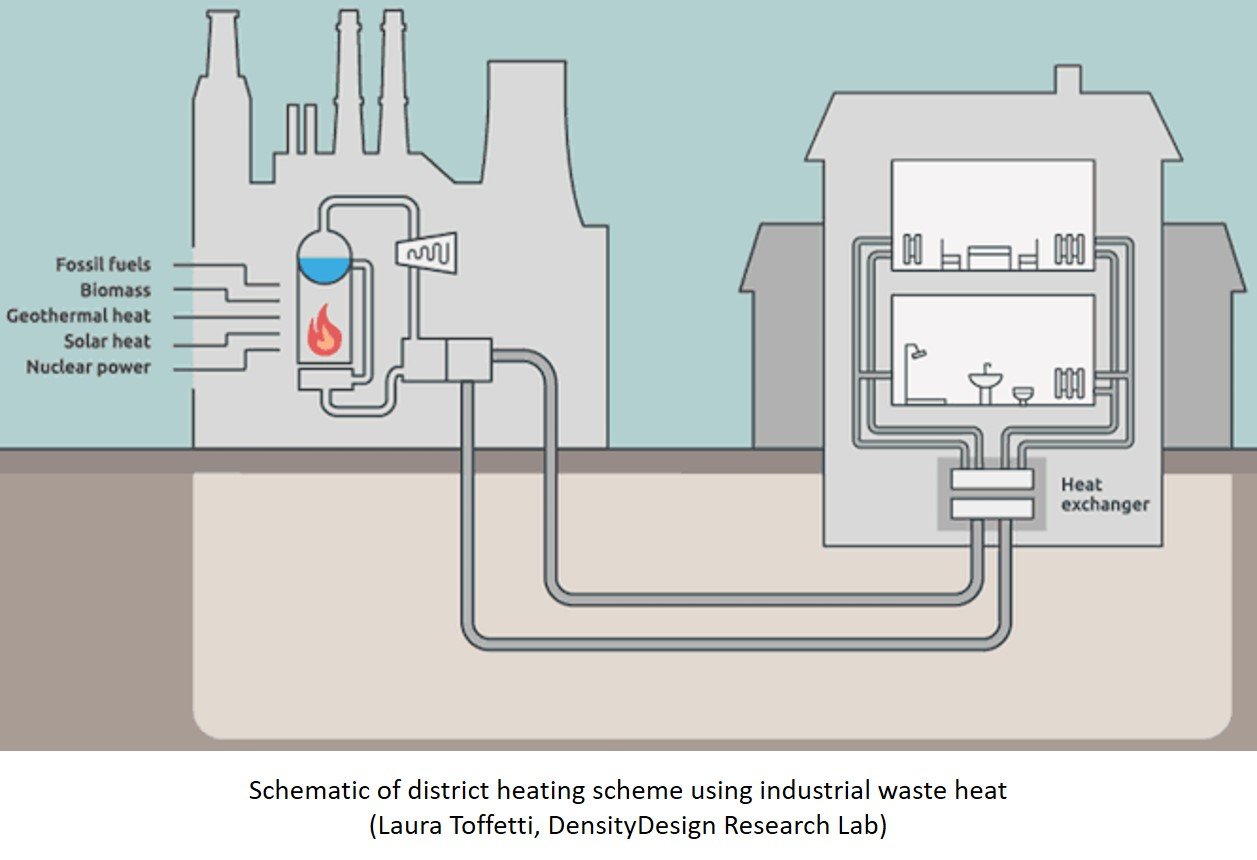

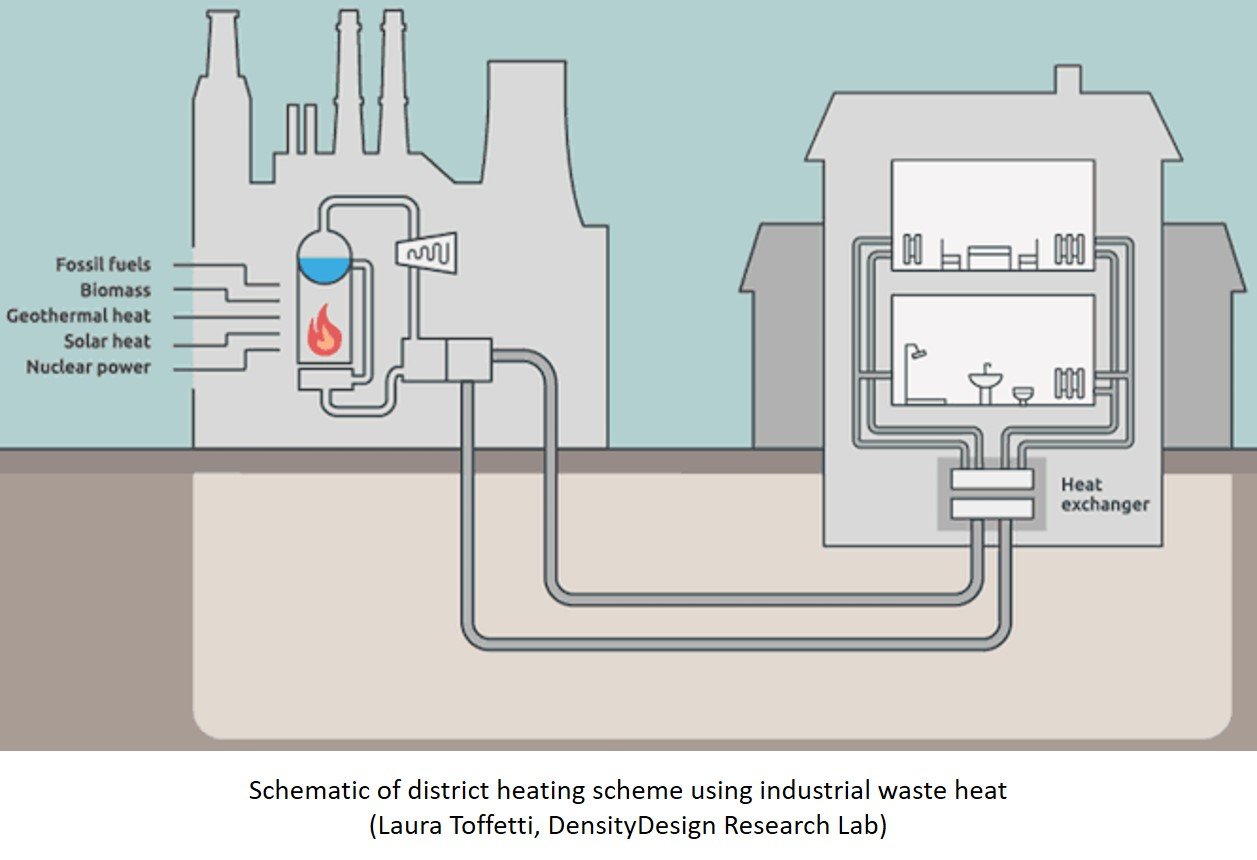

District heating schemes use a single powerplant to provide heating and hot water to many buildings. They have been promoted as important in decarbonising the British...

There are many innovations transforming building services driven mainly by the huge challenge of achieving Net Zero targets. In a series of articles, we look at these innovations specifically where they are appropriate for apartment blocks.

In this final article in the series, we look at using direct electric space heating and domestic hot water heating.

Direct electric space and water heating can replace the need for ‘wet’ central heating in a well-insulated flat. Fast-response heaters automated by a control system are inexpensive to install, avoid the overheating risk inherent to wet heating, and meet or exceed the efficiency of electricity augmented by air-source heat pumps.

|

This article is the fourth in a series on recent innovations in building services for apartment blocks:

Apartment innovations 1: fifth generation heat networks

Apartment innovations 2: heat pumps powering heat networks

Apartment innovations 3: hydrogen in the gas main

Previous articles in this series have considered innovations in apartment heating, ventilation and air-conditioning (HVAC) that requiring considerable investment in infrastructure at the local or national level. An alternative approach is to use building services powered directly by mains electricity.

Electricity is the energy option with the lowest carbon intensity and as renewables replace fossil fuels in powering the national grid, that carbon intensity is projected to halve by 2035. The direct electric option would effectively move the domestic sector from gas to electrical power which would require an increase in renewable electricity generation. However, unlike hydrogen power and fifth-generation heat networks, the necessary technologies are already widely used which means the necessary components are already in mass production and there are established training programmes for the engineers needed to operate and maintain them.

Most building services, including ventilation, appliances and air-conditioning, are already powered directly from the mains. The major innovations required for the direct electric building are in space and water heating.

Direct electric space heating usually involves a simple panel heater in each room, which is inexpensive to install and requires little maintenance. The systems replaced by direct electric heating, whether the gas-powered systems that heat most existing homes or the more modern approaches of using heat pump-augmented electric heating or heat networks, involve heating water to distribute heat energy around a building.

Such ‘wet’ central heating systems use a large amount of energy to heat a large volume of water and some of that energy is inevitably lost as the water is pumped from the heat source to radiators or underfloor heating. In an apartment block, that heat is likely to build up inside the building and contribute to overheating in the summer but wet heating systems do not deliver more cost-efficient heating than the direct electric option.

|

|

Electric panel heater in a bedroom (Dimplex) |

We found further evidence for the superiority of direct electric power when we compared data from a post-occupancy evaluation of direct electric flats with a model in which the same flats used an air-source heat pump. Not only did the direct electric option once again prove superior to the heat pump option but when we compared the results to the recommendations of the government’s recent Future Homes consultation on the upcoming revision to energy performance regulations, we found the direct electric flats had been meeting the Future Homes requirements before they were even drafted.

Many existing buildings depend on wet heating because their fabric standards are so poor. The current building regulations mandate minimum standards for insulation and air leakage for new and renovated buildings and those standards will be raised when the regulations are revised. However, most British homes have not been renovated since before fabric standards came into force, leaving them dependent on wet heating.

Britain’s low fabric standards are not sustainable, partly because of the greenhouse gas emissions associated with heating poorly insulated homes and partly because the cost is so high that Britain has one of the highest levels of fuel poverty in Europe [PDF] despite having much milder winters than many European countries; in 2019, more than 10% of British householders could not afford to heat their home properly and the current gas price spike will increase that number this winter.

Improving the fabric of British homes is widely recognised as an important step in both decarbonising the British economy and improving quality of life. It is part of the government’s Clean Growth Strategy and various grants are available for homeowners to improve their insulation.

With high fabric standards both incentivised and mandated, the coming years will see more homes either built with or renovated to the fabric standards for which direct electric heating is a viable option and the advantages of wet heating systems may be outweighed by its disadvantages:

Internal gains from pipework: High-quality building fabric retains heat inside a building during the winter but during the summer, that can drive the temperatures higher than is comfortable. Overheating is already a significant problem in British housing and as summer heatwaves become more frequent, there is a risk that the energy saved in lowering heating bills will be offset by retrofitted air conditioning systems. In many apartment blocks, the problem is exacerbated by internal gains caused by heat energy being lost from hot water pipes which often run through corridors in the centre of the building, where the lost heat cannot disperse without heating the flats along the corridor.

Slow response times: The overheating problem is further exacerbated by the high thermal capacity of water, which leads to a relatively slow response to a thermostat. As radiators and underfloor systems heat and cool in response to a thermostat, they can often cause a room’s temperature to fluctuate between being uncomfortably warm and uncomfortably cold without settling at the optimal temperature.

High installation costs: A wet heating system requires a radiator or underfloor heater in every room likely to be occupied for any length of time, heavily insulated pipes to distribute the hot water and, in the case of an apartment block, fire dampers wherever pipes pass between flats and corridors. The installation cost is considerably higher than simply installing an electric heater in each room and that complexity is reflected by the cost and by higher embodied carbon. The latter is often overlooked problem in schemes intended to cut greenhouse gas emissions. Even when an existing wet heating system is switched from gas to heat pump-augmented electricity, the lower flow temperatures require the radiators and underfloor heaters to be replaced with larger units which amounts to a significant renovation. In an apartment block, a designer is faced with the choice of heavily insulating the pipework or a low-temperature heat network, both of which are substantially more expensive than direct electric heating.

A major advantage of wet heating systems is that they can be powered by a combination (combi) boiler that powers the space and water systems simultaneously. Replacing the wet heating system reduces the amount of water that needs to be heated but hot water is still needed for the taps and showers.

As with space heating, direct electric water heating needs to be compared with heat pump augmentation. The heat pump option has the drawback of only being able to heat water to 55°C (131°F) while gas and direct electric systems heat water to 60-80°C (140-176°F). The lower storage temperature has two drawbacks:

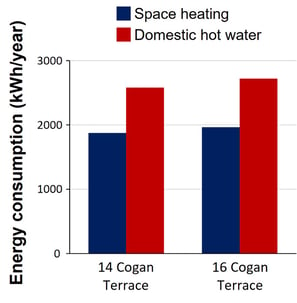

There is no escaping the fact that a large tank of hot water requires a large amount of energy to heat. In our post-occupancy evaluation of flats under direct electric power, we found that heating water accounted for more than half of the heating energy demand:

|

|

Annual energy demand for space and domestic hot water derived from post-occupancy evaluation of two terrace houses, 14 & 16 Cogan Terrace in Cardiff, each rented to seven people divided between three flats. Space heating was direct electric and water was heated by direct electric power augmented by an exhaust air heat pump, all automated by atBOS. |

The challenge of switching from gas to electric power without soaring energy bills has driven a revision of boiler design that uses energy far more efficiently than the conventional approach of simply burning gas to heat water whenever it falls below a thermostat temperature:

The new generation of modern boilers are designed to use electric power, whether direct from the mains or augmented by a heat pump, although some are compatible with hybrid approaches that combine gas and electric power.

New generation boilers provide the sort of efficiency improvements that are necessary to make direct electric power viable, but the single most important facilitator of direct electric power is automation. The reason is that a watt of electricity costs five times more than a watt of natural gas which means that if gas is to be replaced without soaring costs, electric systems need to use energy far more efficiently than the gas systems they replace.

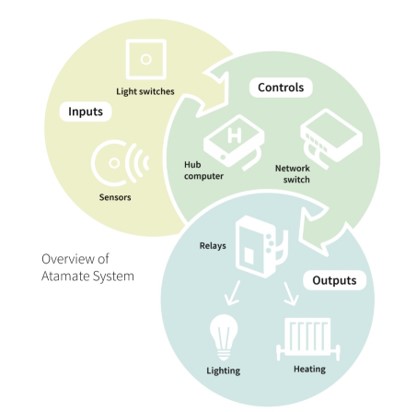

The best way to ensure that energy is used only where it is needed is a single operating system like our own Atamate building operating system (atBOS). The atBOS constantly monitors the indoor environment and applies whatever services are required to keep it comfortable without wasting energy by using them where they are not needed. The key features for maximum efficiency are:

Zonal control applies the services to zones, usually corresponding to a single room, rather than using a single reading for air temperature or quality for the entire flat or building. It ensures energy is used only where it is needed.

Occupancy-based control detects which zones are occupied and keeps them comfortable without wasting energy on heating and maintaining air quality in empty rooms.

Calendar controls allow the home occupiers to set services to switch on or off at predefined times. For example, a flat may be empty during the day when the occupants are at work and during the winter, even a well-insulated home can become uncomfortably cold when it is not heated for several hours. The calendar function allows the occupants to over-ride the occupancy controls and switch on the heating a few minutes before they arrive home, ensuring that it is at a comfortable temperature when they do arrive.

Flexibility allows an off-the-shelf system to be tailored to the services that can be automated in a given home without needing to be redesigned for every installation. For example, most modern homes will have space heating, water heating and ventilation systems but some flats have windows that can be opened while others do not. Automated window-opening gives the system a way to improve air quality with a lower energy requirement than mechanical ventilation and can also be used for passive cooling. The same flexibility allows onsite energy generation systems, such as photovoltaic panels or solar thermal cells, to be used to supplement mains electricity.

Integration of all aspects of the building services under a single control system avoids conflict between different services. To extend the example of the automated windows, automation would switch off any space heating or air-conditioning as soon as the windows are opened. Even where the windows are not automated, they may be fitted with sensors so that opening them manually would have the same effect.

The current generation of building operating systems can be controlled using a phone or tablet but still depend on the home’s occupants setting the parameters for its operation. The next generation is likely to use machine learning so that every system learns the behaviour of the building it is installed in to further improve its energy efficiency.

Direct electric power is our preferred option for a flat that is well enough insulated that it does not need wet central heating.

|

We acknowledge that we are not disinterested; our core product is the sort of operating system needed to make direct electric heating a viable option. However, our product does not commit us to the concept. Our case studies have shown that our system delivers improvements to comfort, convenience and energy efficiency to a wide variety of buildings with different energy sources and service types. Rather, our preference is underpinned by the fast response of direct electric space-heating units, which makes the best use of the occupancy-based zonal control system while avoiding overheating.

Unfortunately, both direct electric heating and automation have been largely overlooked in much of the conversation about decarbonising the domestic sector. Options requiring higher levels of investment, such as hydrogen power, district heating and air-source heat pumps, have been given much more attention by advisory bodies like the Climate Change Committee (CCC) and in government policy documents like the Future Homes consultation.

Our post-occupancy evaluation studies have shown that the combination of automation and direct electric power compares extremely well with other options, delivering a level of energy efficiency that meets even the stringent standards required by the Passivhaus Trust and is compatible with the infrastructure already in place.

However, we do not promote the direct electric option as a generic solution that will be optimal for every apartment block. Our position is simply that it should be among the range of options that should be compared at any project’s design stage and that the comparison should be based on a range of metrics including cost, comfort and carbon.

If you’d like to know more about how the atBOS platform can enhance the energy performance of apartment blocks or any other type of building, ask us on the form and we'll be happy to discuss it.

District heating schemes use a single powerplant to provide heating and hot water to many buildings. They have been promoted as important in decarbonising the British...

A real-world study of rental properties tested how much Atamate controls improve heating efficiency....