There are many innovations transforming building services driven mainly by the huge challenge of achieving Net Zero targets. In a series of articles, we look at these...

There are many innovations transforming building services driven mainly by the huge challenge of achieving Net Zero targets. In a series of articles, we look at these innovations specifically where they are appropriate for apartment blocks.

In this this article of the series we look at the advantages and disadvantages of using hydrogen as an alternative to gas as an energy source.

The British government’s hydrogen strategy calls for a massive expansion in hydrogen production and evaluation of whether it can replace natural gas as the major energy source in the building sector. However, the available evidence suggests that the infrastructural investment would be better directed toward expanding the use of electricity.

|

|

This article is the third in a series on recent innovations in building services for apartment blocks:

Apartment innovations 1: fifth generation heat networks

Apartment innovations 2: heat pumps powering heat networks

Apartment innovations 4: the direct electric option

On the last day of 1813, discerning readers across Britain were enjoying Jane Austen’s newly published Pride and Prejudice, the Duke of Wellington was advancing from Spain into France and the city of Buffalo, New York State, was still smouldering after being burned by the British army. It was also the day when a more benign flame appeared on Westminster Bridge: the first gas-powered streetlights.

Two centuries later, a report by the Institute of Engineering and Technology (IET) estimated that mains gas provides over half of Britain’s energy requirements and contributes about half of Britain’s greenhouse gas emissions. The emissions are due to most of the gas used in Britain being methane, or natural gas, which combusts to carbon dioxide and water vapour. Replacing methane with low-carbon alternatives is a priority for the Department for Business, Energy & Industrial Strategy (DBEIS) strategy on Heat in Buildings, which forms a part of the government’s overall strategy to achieve a net-zero carbon economy by 2050.

![Westminster Bridge with gas-powered streetlights, painted by Malcolm Root probably between 1910-1914 (Leonard Bentley [CC/ Flickr])](https://www.atamate.com/hs-fs/hubfs/Root_WestminsterBridge.jpg?width=483&name=Root_WestminsterBridge.jpg) |

|

Westminster Bridge with gas-powered streetlights, painted by Malcolm Root probably between 1910-1914 (Leonard Bentley [CC/ Flickr]) |

In November 2020, expanding the role of hydrogen was listed as one of ten points in the DBEIS’s plan for a green industrial revolution to set the economy on a course to achieving net-zero. The DBEIS expanded the role of hydrogen from one of ten bullet points into a strategy document in August 2021, stating its ‘ambition is for 5GW of low carbon hydrogen production capacity by 2030 for use across the economy’. The strategy document contains many such statements of aspiration with little detail on how to achieve them or how they will be financed. Fulfilling the strategy is left to an industry coalition called the Hydrogen Taskforce.

The strategy suggests that hydrogen may have a role in industry, transport and in powering buildings but while the first two applications depend on technologies that are still under development, the technologies needed to replace mains methane with mains hydrogen are already mature. However, the strategy document acknowledges that the jury is still out on the question of whether it is the solution that the domestic sector is looking for:

Before hydrogen for heating can be considered as a potential option to decarbonise heat in buildings, we need to generate further evidence on the costs, benefits, safety, feasibility, air quality impacts and consumer experience of using low carbon hydrogen for heating relative to other more established heat decarbonisation technologies. (DBEIS 2021 UK Hydrogen Strategy p62).

Mains hydrogen would not be new to Britain. Before gasfields were discovered under the North Sea in the 1960s, mains gas was manufactured from coal and comprised a mix of flammable gasses collectively called coal gas or town gas. Hydrogen made up around half of the mix by volume, meaning that those first gaslights on Westminster Bridge were largely powered by hydrogen.

However, the pure hydrogen envisaged in the British hydrogen strategy would be very different to the town gas that once heated British homes. Developing it would require a considerable investment in both manufacturing facilities and in converting the distribution system which is why the strategy calls for evidence to establish whether such an investment would be worthwhile.

Several studies on the subject have already been carried out and while the evidence may not be comprehensive enough to provide a final answer to the DBEIS’s questions, hydrogen power has been field-tested on a small scale and several studies have modelled its rollout on a regional or national scale.

|

|

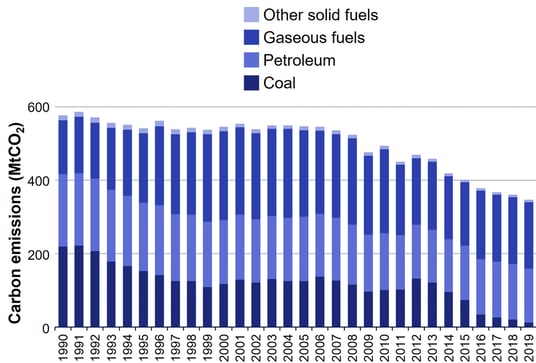

UK carbon emissions by fuel type 1990-2019. Adapted from DBEIS (2021) 2020 UK greenhouse gas emissions, provisional figures. |

There are three main sources of pure hydrogen that each have their own strengths and weaknesses.

For the foreseeable future, the main source of hydrogen is likely to be ‘blue’ hydrogen: splitting methane into hydrogen and carbon dioxide through steam methane reforming (SMR). Other techniques are under development but SMR is the only technology mature enough for the timescale envisaged by the government’s hydrogen strategy.

Blue hydrogen’s biggest advantage over natural gas is that it can be combined with carbon capture and storage technologies. According to a white paper published by the International Council on Clean Transportation (ICCT), combining SMR with carbon capture would cut greenhouse gas emissions by 42-61% when compared to natural gas or if hydrogen were used to power the SMR process, the cuts would be at 69-93%.

To be carbon-neutral, carbon offsets would need to be factored into the cost of blue hydrogen but it would deliver considerable reductions when compared to methane.

An alternative approach is to produce hydrogen by passing an electric current through water to electrolyse the water molecules into hydrogen and oxygen. If the electricity is derived from carbon-neutral sources such as renewable or nuclear power, then the hydrogen produced is carbon neutral.

The limitation of ‘green’ hydrogen is the enormous amount of electricity needed to generate enough green hydrogen to replace an appreciable amount of natural gas. The 2017 H21 study [PDF], which assessed the feasibility of converting the city of Leeds from natural gas to hydrogen, calculated that wind farms covering 400-500km2 would be needed to fill the Leeds gas main and Leeds only contains approximately 1% of the British population.

The H21 authors commented that large-scale production of green hydrogen may be possible in countries like Iceland, with its effectively unlimited geothermal power but in Britain, there is no prospect of generating enough electricity to replace a substantial proportion of natural gas needs with green hydrogen.

While most mains methane is derived from fossil fuels, organic material decaying in the absence of oxygen offers an alternative source. The bacteria that thrive in such anaerobic conditions produce methane, which can be used to generate electricity. Alternatively, the biomethane could be split to produce hydrogen using the same processes that generate blue hydrogen and as with blue hydrogen, the carbon dioxide can be sequestered.

A particularly attractive feature of the combination of biomethane-derived hydrogen with carbon sequestration is that it could provide carbon-negative energy, meaning that energy generation would involve a net decrease in atmospheric greenhouse gasses.

Moreover, biomethane-derived hydrogen is subject to the same limitation as green hydrogen: the prospect of clean energy does not overcome the limits of its capacity. There is no way to produce enough biomethane to supply more than a small proportion of the hydrogen that would be needed to fill Britain’s gas mains. Most biomethane currently produced is used to generate electricity, which can also be combined with sequestration, and it is not clear that using the biomethane as a source of hydrogen would amount to a more cost- or carbon-efficient way to generate energy.

If hydrogen production were expanded to replace natural gas in the national grid, the infrastructure of the grid itself would need to be modified to accommodate it.

At present, much of the distribution network uses steel piping which is not suitable for hydrogen because of the phenomenon of embrittlement: hydrogen atoms diffuse into the steel and raise its internal pressure, causing metal fatigue that ultimately leads to cracks in the structure. Replacement of steel pipework is already underway with the Iron Mains Replacement Programme scheduled to replace all metallic gas pipes with polyethylene, which can carry either hydrogen or methane, by 2032.

However, the problem remains that the hydrogen molecule is far smaller than the methane molecule and that a seal tight enough to prevent methane from leaking may permit a hydrogen leak. Consequently the level of wastage would be higher with hydrogen than methane.Worse, it would increase the likelihood of leaks serious enough to cause explosions.

A further problem is that hydrogen’s energy density is about a third that of methane, meaning that three litres of hydrogen need to be burned to deliver the same energy as one litre of methane. Converting to hydrogen would mean three times as much gas would need to be pumped through the mains,requiring higher pressures that would increase both the likelihood and volume of leaks. The higher volume of gas required would also require substantial investment in storage facilities.

Another concern is that because the international market for hydrogen is tiny, Britain would be dependent on domestic production and would require substantial investment in storage facilities.

Five decades of natural gas has left homes across the country equipped with boilers and cookers designed to burn natural gas but those appliances would not be suitable for hydrogen for two reasons:

A programme to replace mains methane with hydrogen would need to include the replacement of the appliances. Scrapping appliances before they reach the end of their lifespan would add to the carbon budget of the project as well as incurring a substantial cost.The H21 study’s authors estimated that replacing gas cookers and boilers would cost £842 per property, adding up to a total of £1 billion for all of Leeds. That’s not an astronomical cost for an infrastructural project; for context, the 2010-2015 redevelopment of Birmingham New Street Station cost £750 million and the 2020 Eat out to Help Out stimulus to the hospitality industry cost the exchequer £849 million. Nevertheless, it would be a large enough investment in only one part of the project to require clear evidence that it would be money well spent.

As well as the financial burden, replacing appliances would involve significant disruption to the homes and other buildings that they were being replaced in. The H21 study envisaged switching homes in blocks of 2,500 at a time between April and September, when heating demand is relatively low, and anticipated that no home would be disconnected for more than five days. It does not explain how people with gas cookers would prepare their meals in that time.

An alternate approach is to use dual-fuel appliances, which are compatible with either methane or hydrogen, rather than appliances designed to operate on hydrogen alone. Dual fuel appliances could be installed on a home-by-home basis before the switchover from methane to hydrogen, reducing the disconnection time from days to hours. The drawback is that an appliance compatible with both fuel types requires the sensors needed for both fuel types, which raises the question of whether the short interim period between the appliance upgrade and the switch from methane to hydrogen would justify the expense.

Keele University’s HyDeploy project pioneered another approach: blending hydrogen with methane. The existing network and appliances can carry a methane/hydrogen mix of up to 20% hydrogen without requiring modification although because of hydrogen’s lower energy density, that 20% of hydrogen in the mix would only deliver 7% of the energy.

The Keele University campus gas main is isolated from the national grid, so HyDeploy was able to trial an 80/20 methane/hydrogen mix on 100 homes and 30 faculty buildings starting in the autumn of 2019. The mix emitted less carbon than pure methane and none of the gas users noticed any difference. The project is currently entering its second phase [PDF], involving a broader trial of homes in northern England.

Mixing gas would allow hydrogen from various sources to be used to reduce or, in the case of biomethane-derived hydrogen combined with carbon sequestration, to offset the greenhouse gas emitted by burning natural gas. It could be initiated as soon as hydrogen is available and would not need to wait for hydrogen production plants to be built or for the distribution network to be reconfigured.

Once fuel-appropriate appliances are installed, the difference between methane and hydrogen is unlikely to be discernible in terms of cooking or heating but the first question in a customer’s mind will inevitably be how it will affect their energy bills. The H21 project projected the following costs:

Those figures fall between UK Power’s mid-2021 estimates for electricity at an average of 14.4p/kWh across Britain and natural gas at 2.8p/kWh. At the time of writing, international gas prices are at a historical high but they is likely to normalise before an appreciable amount of hydrogen can be fed into the gas main. Nevertheless, the comparison is not as straightforward as simply comparing the cost-per-unit energy.

Air-source heat pumps can double or occasionally triple energy drawn from mains electricity, which wouldn’t bring the cost-efficiency of electricity to parity with natural gas but it would beat blue hydrogen’s 7.3p/kWh even before the cost of appliance switching was factored in.

The ICCT also found that hydrogen compared unfavourably with electricity augmented by heat pumps. The disparity was so great that even if electricity prices were 50% above the value they projected, heat pumps would still have the edge:

Our view is that there is sufficient evidence to address the questions raised in the DBEIS’s hydrogen strategy document and that evidence does not support replacing natural gas with hydrogen in the building sector.

It is necessary to break the housing sector’s dependence on natural gas, largely to curb greenhouse gas emissions but also because the recent price shock raises the question of whether it will continue to be as cost-effective as it has been in the past. Replacing natural gas with hydrogen would not achieve that goal because it could only be done with blue hydrogen, which is itself derived from natural gas.

Large-scale investments in the building energy infrastructure would be better directed toward expanding the role of electricity, which promises better cost-effectiveness and lower carbon emissions than hydrogen.

All the published comparisons between hydrogen and electricity assume that electric heating would be augmented by heat pumps but we have found that even some of the more optimistic projections of the value of heat pumps compare unfavourably with direct electric power so we would like to see a comparison between hydrogen and direct electric space and water heating.

While we do not expect to see the sort of pure hydrogen infrastructure projected in the H21 project, the HyDeploy project has raised the possibility of using it to reduce greenhouse gas emissions from mains gas that could be put into practice immediately. The prospect of carbon-negative energy from biomethane-derived hydrogen is particularly attractive, although it should be subject to a comparison of the financial and carbon budgets of the process with sequestering carbon from biomethane burned to generate electricity.

Hydrogen may have significant applications in transport and industry but all the available evidence supports our view that investment in the building energy sector is better directed toward expanding the role of electricity than toward replacing the natural gas in the mains with hydrogen.

If you’d like to know more about how the atBOS platform can enhance the energy performance of apartment blocks or any other type of building, ask us on the form and we'll be happy to discuss it.

There are many innovations transforming building services driven mainly by the huge challenge of achieving Net Zero targets. In a series of articles, we look at these...

Yesterday, the government announced a £450 million boiler upgrade scheme, offering £5,000 grants for households replacing gas-boilers with low-carbon heating systems....